1.Brief introduction of GOT micro-channel heat exchanger

GOT Micro-Channel Heat Exchanger is a brand new heat transfer technology upgrading product,It has revolutionized the heat exchangers used in all industries.The working principle of its core component "heat exchange core" is the same as that of activated carbon,i.e. the internal microchannel structure forms a very large surface area,(more than 10 times of the heat exchange area of shell and tube heat exchanger with the same volume).At the same time, the tightly combined flow passage of cold and hot media greatly improves the heat transfer efficiency.

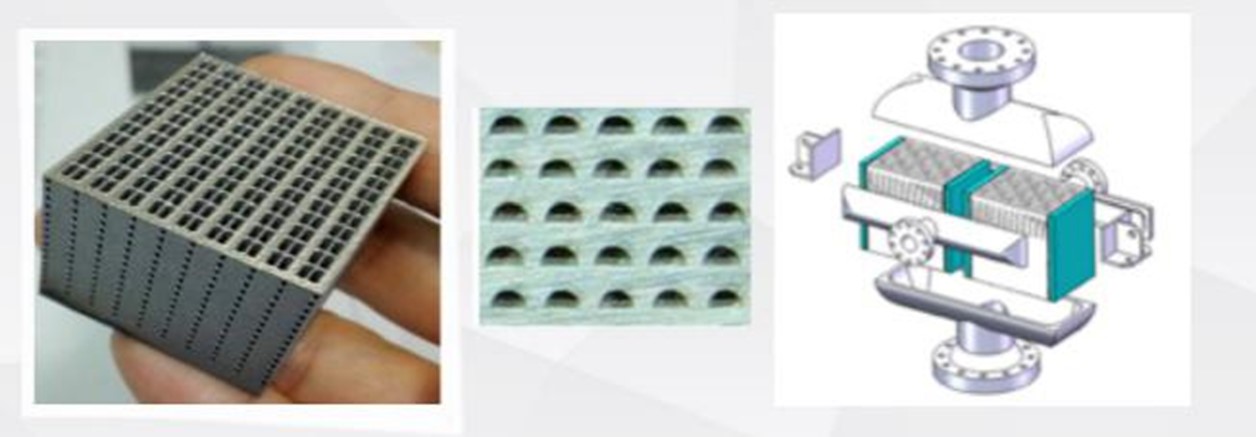

1. The heat exchange core of GOT micro-channel heat exchanger

The processing technology of GOT micro-channel heat exchanger is similar to that of chips,It is to use chemical etching technology to etch heat exchange unit channels of micrometer to millimeter scale on the metal sheet to produce heat exchange core plates.Then stack the cold and hot core plates of different flow channel forms alternately,through diffusion bonding technology, the adjacent core plates are closely combined to form a heat exchange core.

2.Application of diffusion bonding process in micro-channel heat transfer technology

Due to the special structure of the micro-channel core, a large area of connection between the core plates requires a large number of welded joints.Conventional heat exchangers are usually welded by fusion welding process.Fusion welding technology is mature and easy to realize, but it requires good accessibility of welded joints.For the special structure of micro-channel heat exchanger core, fusion welding technology is not easy to realize.

2. GOT Micro-channel Core Plate Connection Drawing

2.1 What is diffusion bonding process.

Diffusion bonding is a solid-state joining process that can obtain integral welded joints. i.e.by means of local plastic deformation between materials in contact with each other at high temperature,the atomic diffusion is formed between the contact surfaces of two workpieces,so as to realize a precise connection.

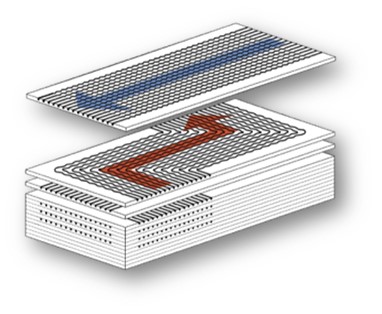

3. Dynamic diagram of diffusion bonding connection interface

The bonding area increases due to the deformation of micro roughness at the bonding surface,and the bonding starts by using an atomic diffusion.After that,crystal grains grow across the faying surface and the bonding interface becomes indistinguishable.The tensile strength of diffusion bonded joint at room temperature is equal to that of base metal.

Diffusion bonding is a technology that enable the manufacture of products with fine and complex internal structures,and is generally used where it is difficult or impossible to form a joint,for example,in components that have a complex internal structure.A common application for diffusion bonding is compact heat exchangers.

2.2 Brief introduction of diffusion bonding process.

The diffusion bonding furnace used for GOT micro channel heat exchanger is a vacuum furnace, equipped with hydraulic ram, which applies pressure to the core plate to be connected through the graphite tool. This process is called uniaxial diffusion bonding. Since this process depends on atomic diffusion, it is necessary to apply pressure to make the two surfaces contact closely, so as to promote the diffusion between interfaces. Therefore, the surface roughness and flatness between core plates are important process parameters.

4. GOT Diffusion Bonding Furnace

Diffusion bonding is commonly performed under vacuum at a level <1×10-2mbar and at temperatures up to 1300℃.

Higher temperatures are required for materials with a higher melting point.as the diffusion bonding temperature is typically 50%—75% of the material’s melting point(Tm).At the same time, when conducting diffusion bonding, the maximum load limit of the furnace itself should also be considered to determine the most appropriate welding temperature.

Certain materials are not compatible with high vacuum conditions,in which case,diffusion bonding under the partial pressure of an inert gas,such as Argon or N2,is common.

5. GOT Diffusion Bonding Furnace

2.3 Advantage of diffusion bonding process.

1). During diffusion bonding, since the matrix is not overheated or melted, almost all metals or nonmetals can be welded without reducing the properties of the materials to be welded, especially suitable for fusion welding and materials difficult to be welded by other methods, such as active metals, heat-resistant alloys, ceramics and composites. For the same materials with poor plasticity or high melting point, as well as the dissimilar materials that do not dissolve each other or produce brittle intermetallic compounds during fusion welding, diffusion bonding is a more appropriate welding method.

2). The diffusion bonded joint has good quality, its microstructure and properties are similar to or the same as those of the base metal, and there are no fusion welding defects, overheating structure and heat affected zone in the weld. The welding parameters are easy to accurately control, and the joint quality and performance are stable during mass production.

3). The weldment has high precision and small deformation. Due to the low pressure applied during welding, the workpiece is generally heated as a whole and cooled with the furnace, so the overall plastic deformation of the weldment is very small, and the workpiece after welding is generally not subject to mechanical processing.

4) Large section workpieces can be welded. Because the pressure required for welding is not large, the tonnage of equipment required for large section welding is not high, which is easy to achieve.

5) It can weld workpieces with complex structure, inaccessible joints and large thickness difference, and can weld many joints in the assembly at the same time.

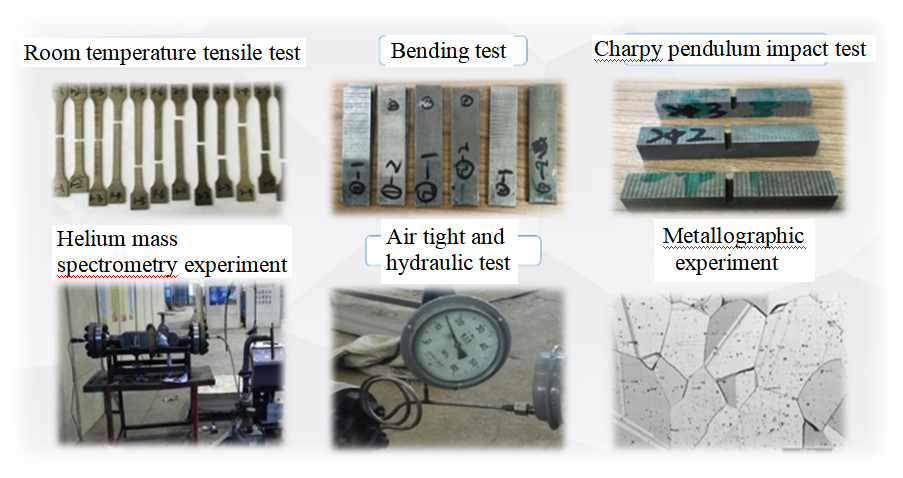

3.Quality assurance of GOT micro diffusion bonding products

Ø Physical and chemical tests such as tensile test, bending test and impact test on product test pieces

Ø NDT equipment is complete

Ø Hydrostatic test shall meet the requirements of national standards

Ø Air tightness withstand voltage test

Ø Helium mass spectrometry

Ø Strength test

Ø Blasting test

6. Photos of the inspection process of GOT micro diffusion bonding products

GOT diffusion bonding expert worthy of your trust!